General

Inquiry Form

Hull Unit

Home Base for Fins & Rotors

Hull Units for Fins

Hull Units for Fins

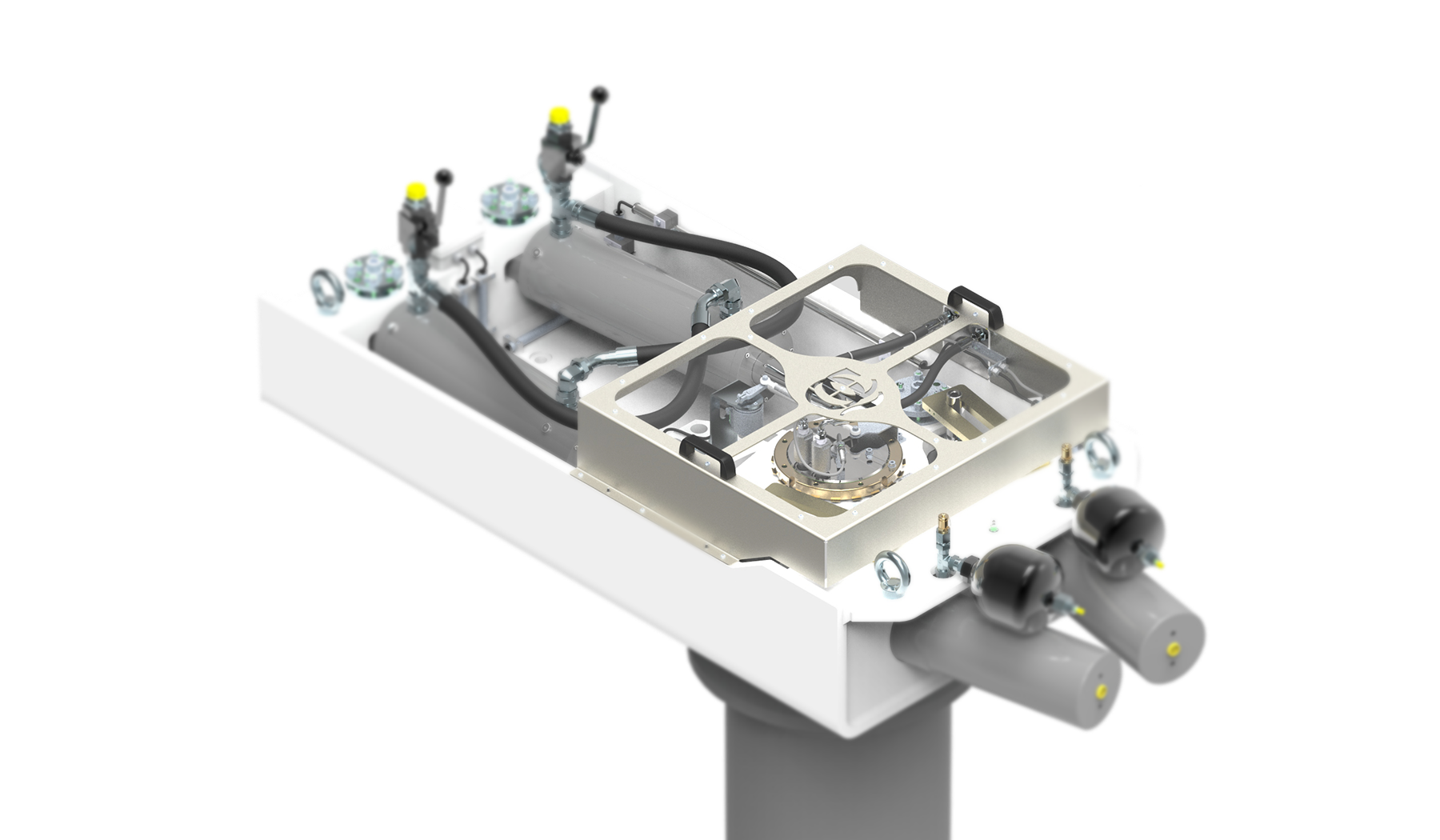

The hull unit is one of the major component parts in a Quantum stabilizer. It interacts with the controls, stabilizer fin and hydraulic power unit to deliver precise movements of the fin as is commanded by the control system.

The hull unit is installed in the turn of the bilge with the main shaft penetrating the hull providing the apparatus to connect the stabilizer fin. The hydraulic cylinders on the top of thehull unit, rotate the main shaft, which deflects the fin to the precise position as directed by the control system.

The installation is managed through the supplied welding bushing. The main shaft features a tapered hydraulic expansion coupling for the secure attachment of the fin, and a spline connection to the tiller and hydraulic cylinders. These precise machined components promote a smooth transfer of energy from the hydraulic cylinders to the stabilizer fin.

The hull unit is simple to maintain during normal operation, with stainless steel components used to minimize corrosion. Internal porting is built in, providing grease points that are accessible from inside the vessel, making routine maintenance easier. The unit is designed for replacement of the lower seals and bearings during regular scheduled docking. All other internal maintenance and service work can be accomplished with the vessel in the water.

All standard and HD hull units in the Quantum model range can be upgraded to support the installation of XT™ fins. Hull units can be delivered with the appropriate XT™ components preinstalled for conversion at a later date.

For safety and emergency operations, all Quantum hull units are equipped with centering cylinders. These cylinders engage the tiller and have the capacity to center and lock the fin in the mid position should there be a failure of the main cylinders, hydraulic power unit or control system. The cylinders can be deployed from the main power unit or if required, can be deployed using a manual hand pump.

New Rack & Pinion Hull Unit – “R Series”

New Rack & Pinion Hull Unit – “R Series”

Introducing the new rack and pinion actuator (hull unit), the “R Series,” designed specifically to maximize the performance of Quantum’s Fixed and XT™ Fins

Quantum capitalized on their experience and service history with the MAGLift™ Rotor rack and pinion system to then re-engineer and advance the R Series technology. Through complex computational fluid dynamic (CFD) studies and precise model testing, this new system offers incredible advantages:

- the shaft is fitted with roller bearings, both top and bottom that have an estimated 15,000 hour replacement schedule, significantly extending the time between haul outs and reducing maintenance costs

- the hydraulic cylinders can be rebuilt in place, eliminating the very challenging cylinder replacement process. This single feature, represents significant savings:

- it greatly simplifies the cylinder maintenance process

- it reduces the service and down time of the vessel

- it results in much lower maintenance costs

- in certain applications, the increased swing capacity, up to 45 degrees in each direction, can greatly improve zero speed performance

- the hydraulic locking mechanism provides double security for locking the fin and shaft in place when the system is not in use or while being serviced, even out of the water

- there is also a manual locking pin in case of an emergency and the system requires immediate locking

- the compact design and mounting arrangement is perfect for retrofits to either upgrade or replace other existing systems

- the rack and pinion unit results in a much smaller footprint, where engine room space is always coveted

- with four pistons and dual racks, it exerts the full range of motion with constant torque on both sides of the gear wheel, equating to greater efficiencies and quieter operation

- rapid acting relief valves, transfer the oil and rotate the fin to initiate the release of the drive mechanism should the vessel encounter an unexpected impact, broaching or slamming loads.

- to simplify the operation and maintenance, the gear case is lubricated with the same hydraulic oil that is used in the hydraulic system

Fin and Rotor Hull Units

Fin and Rotor Hull Units

Fin Hull Unit Series

QC1500

QC1800

QC2200

QC2500

QC3000

QC3600

QC4000

LOA Range (m)

36-50m

45-60m

55-65m

60-90m

80-110m

100-152m

115-200m

Standard Fin Range (m2)

1.5 - 3.5

3 - 5

4 – 6.5

6 – 8.5

8 – 10.5

10 – 15

12 – 16

XT Fin Range (m2)

3 x 4

4.5 x 5.7

6 x 7.8

8 x 10.4

10.5 x 13

15 x 19.5

15.5 x 20

Rotor Hull Unit Series

ML300

ML400

ML600

LOA Range (m)

35-50m

45-70m

100-160m

Rotor Length

2500mm

3220mm

4000mm

Rotor Diameter

344mm

460mm

630mm

Note:

All reference to hull unit capacity by vessels LOA is for generalization purposes only. Fin to hull unit sizing is for reference only. For actual sizing please contact Quantum. In addition to our standard hull unit sizing and fin configurations, Quantum also builds custom designed units and fins for series applications.

Hull Units for Fins & Rotors

Simple Installation

Smooth Operation

Precision Control

Efficiency

ML Rotor Retractible Features

ML Rotor Retractible Features

Designed using the latest technology and high-quality materials, the ML Semi-Retractable Series system offers the best performance of any system where significant roll reduction is required at loitering speeds.

Simple Installation: The stabilizer unit is delivered fully assembled with minimal disassembly required for installation. Since no customized hull pocket is required for the rotor’s stowed position, complicated hull shape fabrication is avoided.

Smooth Operation: The unit provides smooth power transfer from the ship’s hull to the rotor via precision roller bearings used in both the spin drive shaft and the main shaft.

Precision Control: By varying the RPM and direction of rotation of the tube, the lift force can be controlled with razor sharp precision, resulting in instantaneous response.

Efficiency: When properly sized and operating within acceptable vessel speeds, rotary stabilizers provide exceptional hydrodynamic efficiency compared with other stabilizer systems available.

Safety: The rotor’s hydraulic system is equipped with an automatic retract mechanism to allow the rotor to swiftly stow in case of impact during operation. While not in operation, the rotor is elegantly stowed along the hull, where it presents minimal possibility of impact and minimal effect during maneuvering conditions. In case of severe impact, half of the rotor tube will break away, in a design feature intended to sacrifice the rotor unit in order to preserve hull integrity.

Hull Unit - controls, hydraulics and fin interface

- Proprietary - Tapered pin bearing interface to extend lifecycle

- Parker quality hoses & fittings

- Proprietary - heavy duty hydraulic swivel

- Accumulators for silent retraction

- Centering cylinders - for stowing & reversing manuevers