General

Inquiry Form

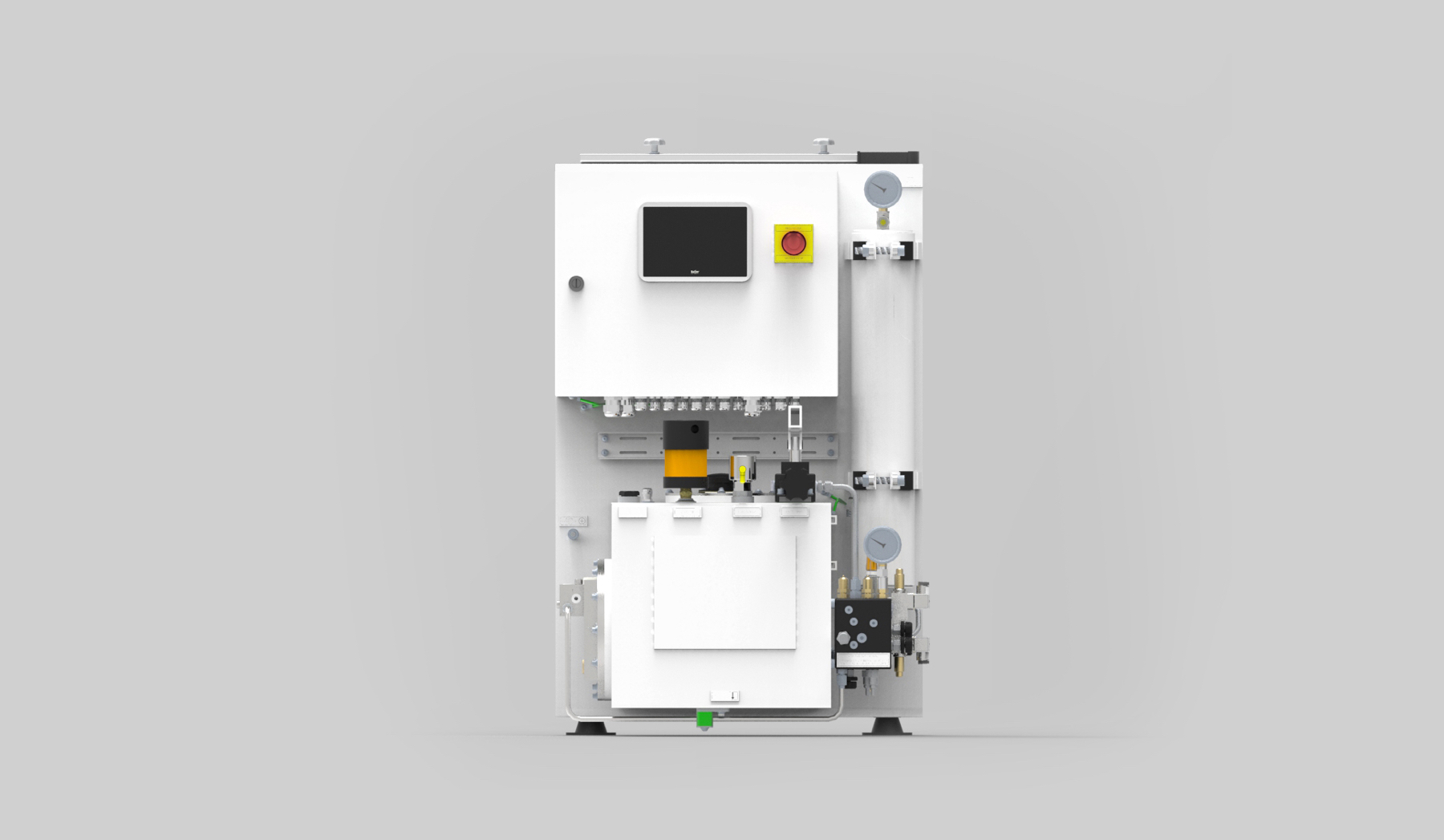

XT™ T3 HPU

XT™ T3 HPU

The XT™ hydraulic power unit (HPU) is specifically designed to extend and retract the foil on the XT™ stabilizer fin.

These functions are controlled via the XT™ HPU instead of the main stabilizer hydraulic system to:

- isolate the submerged cylinder hydraulics from the main hydraulic system

- allow the use of environmentally friendly oil

The XT™ fin is designed with a retractable foil for underway, and extends for zero speed™ operations. To control these activities, the XT™ HPU is a constant pressure system, running only when required to position and hold the foil.

The XT™ HPU is compact. Within its small reservoir, it houses a submerged hydraulic pump, as well as three levels of filtration. Control manifolds on the face of the reservoir contain necessary valves to control the XT™ cylinder position, over-ride and troubleshooting mechanisms, and manual control functionality in case of an emergency.

Control of the XT™ HPU hydraulics is provided by a PLC-based electrical control box. The control box is fitted with a touchscreen display providing real-time foil position indication, hydraulic system status indicators, local power unit and foil operation, and alarms.

Ethernet connection at the XT™ HPU allows shared communication of the position, status and alarms from the system to the bridge. Many of these indicators are also provided for indication on the ship’s central alarm and monitoring system.

Quantum’s XT™ systems utilize hydraulic cylinders to extend the foil contained within the body of the stabilizer fin. Each fin’s extend-retract cylinder is powered by either a single or dual onboard XT™ Hydraulic Power Unit (HPU).

Quantum designed the XT™ HPU to be independent of the main stabilizer hydraulic system to enable the use of eco-friendly hydraulic fluid in the submerged XT™ extend-retract cylinder. The XT™ HPU panel holds the fluid reservoir which contains an immersed hydraulic pump, and the electrical control box. The tank and control box can be removed from the panel for added installation flexibility. The unit offers visual display of foil position and numerous feedback and gauging points.

Key advantages of the XT™T3 Hydraulic Power Unit

Simple Installation

Efficient

power necessary to operate the hydraulic components on demand, thus reducing the load on the vessel’s electrical power system

Appearance

public spaces of even the highest quality yachts. Details such as polished stainless steel tubing and black anodized manifolds make this unit a work of art as well as a practical marine-grade solution.

Environmental Awareness

underwater XT™ fin hydraulic cylinder form a completely separate hydraulic system. Thus, bio-friendly hydraulic oil may be used to power the XT™ cylinder

to minimize possible negative impact on the environment.

XT™ T3 HPU

- Gas pressure gauge

- Modern touchscreen

- Manual backup hand pump

- All electronics are low-smoke & halogen free

- Control manifold with manual overrides